48

Geotechnical News • June 2016

GROUNDWATER

interface. During the autumn, the

lagoons were filled with cold water

and the temperature of the pipes

decreased to 5-10ºC: the 25-30ºC

change made the pipe diameter

decreased by 1-2 mm for pipes having

a diameter in the 30-60 cm range.

Unfortunately, the clay used for the

liner had no swelling capacity: it was

unable to follow the pipe thermal con-

traction. As a result, there was a small

annular space around each pipe, and

some arching effect in the clay. The

pore space existed when the lagoons

were filled (cold water in autumn)

and during the full-scale leakage tests.

Thus, a preferential leakage started in

the annular space. This leakage eroded

the clay and enlarged the initially

small space, up to 5–8 cm, during

the time the water level fell from its

maximum elevation down to the pipe

elevation, where the leak around the

pipes went dry.

This clay liner project provided a les-

son for subsequent projects in Quebec.

The design of seals around pipes was

modified. The next seals were made

using a rich soil-bentonite mixture,

30- to 50-cm thick. When the dry mass

of bentonite is 16-20% of the total dry

mass, the mixture can follow the pipe

thermal contraction and dilation with-

out losing the hydraulic seal. Such a

solution appears

in a photograph

for a much larger

project with large

pipes (see Fig.

8 in Chapuis

2002). In his

files, the author

has over twenty,

mostly unpub-

lished, cases of

failure for soil-

bentonite liners

and compacted

clay liners, but

this case (one of

earliest cases of

liner construction

and liner failure

in the author’s

files) was the

first and last one with a sealing defect

around plastic pipes.

Reconstruction in the

mid-1980s

The upper parts of the liners were

rebuilt with the same clay. The field

geotechnical control was continuous

instead of part-time during initial con-

struction. For reconstruction, it was

suggested that the pipes be sealed with

a soil-bentonite mixture. This sugges-

tion was followed by the consulting

engineer and used by the contractor.

Immediately after the repairs, the

two lagoons were filled, up to their

top levels. All valves on the pipes

were closed, and the leakage rate of

each lagoon was measured. The two

liners passed the new tests and were

accepted. Since the 1980s, they have

performed well, as indicated by their

low leakage rates, which can be moni-

tored in the filtering-drainage system

below the liners.

Availability of new predictive

and control tools

In the 1980s, predictive and control

tools had serious limitations. This was

an incentive to develop closed-form

solutions for analyzing full-scale leak-

age tests and detecting the position

and stability of different types of

hydraulic defects. Closed-form solu-

tions were developed and then verified

with a few poorly performing liners.

They provided correct diagnoses, and

all liners were successfully repaired.

Afterward, closed-form solutions were

published (Chapuis 1990a, b). These

were also used to predict the infill-

ing rate of shallow lagoons which are

filled slowly once a year, then emp-

tied, and for which meteorological

conditions, which can bring 50 cm of

rain water or snow water, may be criti-

cal (Chapuis 1991a, b). Later, equa-

tions were developed to predict the

K

value of compacted clay (Chapuis

2002, 2012; Chapuis et al. 2006):

these equations use field compaction

data to predict a

K

value at each place

a compaction control was carried out.

Recently, a statistical method was also

developed (Chapuis 2013) to predict

the full-scale leakage of a liner, using

the small-scale

K

values predicted

with compaction control data.

The 1990 closed-form solutions were

proven correct in a few published

cases (Chapuis et al. 1992; Chapuis

2002), but the author has only pub-

lished a few of the many failure cases

for which he was an expert. The

closed-form solutions for the local val-

ues of

K

, and the resulting large-scale

value of

K

, were verified recently

(Chapuis 2013) for a case of frost

damaged liners. More case studies are

needed for full proof of correctness.

The compaction data of the two clay

liners of this paper, built and success-

fully repaired in the 1980s, provide an

opportunity to test the new predictive

methods, because they permit direct

comparison between predicted and

measured total leakages. This detailed

comparison will be presented in

another paper.

Discussion and conclusion

Two compacted clay liners were

constructed, tested for full leakage,

poorly performed, but were success-

fully repaired in the 1980s. Both liners

failed the first full scale leakage tests.

Each liner had a total leakage rate

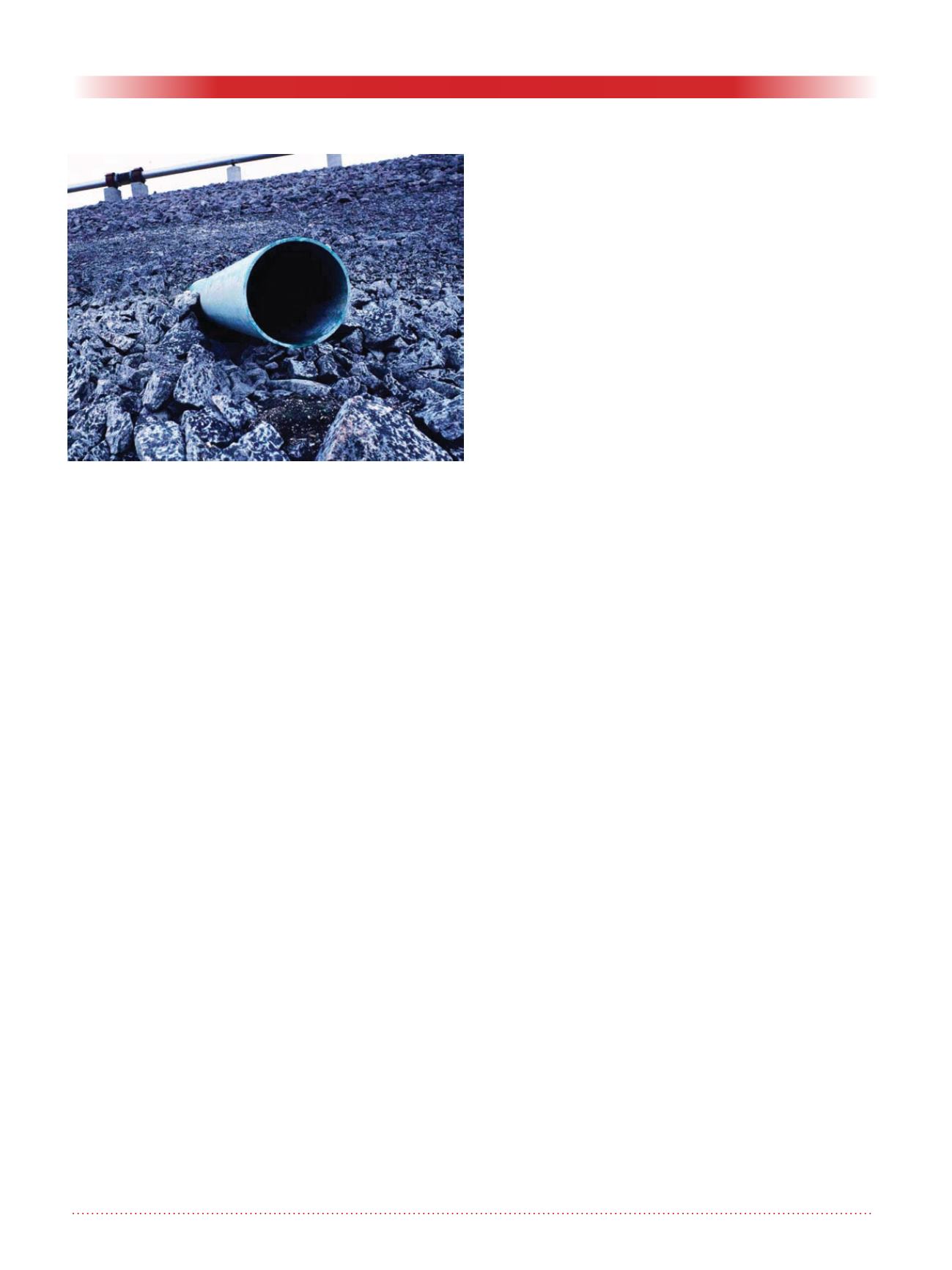

Figure 4. Photograph of the poor contact between a pipe

and the clay liner (photo by author). A large opening

appears as a black crescent below the pipe.