42

Geotechnical News • March 2016

THE GROUT LINE

and the drainage of the embankment

through the up-stream face after the

reservoir draw-down.

In order to limit potential damage

to the core and to avoid the risk of

heave, the injections commenced

with a relatively modest GIN value

of 1,000. The early section of the

works was phased so that the grouting

engineer could very quickly observe

the effectiveness of the ground treat-

ment over the primary and secondary

phases for a limited section of both

the upstream and downstream grout

curtain. The reduction ratio achieved

for the grout volumes injected in the

four successive phases was lower

than was anticipated, and the GIN

value was therefore increased to 1,200

to allow slightly greater pressures

and greater maximum volumes to

be applied for the remainder of the

works, whilst retaining the same target

volume per linear metre, and the same

limiting maximum pressure. A single

GIN value was selected for the entire

works.

At Carno, the GIN system was applied

with particular care, partly because of

the reduced confinement arising from

the reservoir draw-down, and partly

to ensure that the results at the end of

the secondary phase met the specified

requirements, with no requirement

for a tertiary phase. The software

displayed real-time plots of basic

injection parameters, together with an

additional completion criterion, - the

‘Equivalent Lugeon’ value. This value

combined the volume, pressure, and

time data for the injection in progress,

and calculated an Equivalent Lugeon

value, by taking into consideration

the relative viscosity of the grout

mix to that of water. This function

was clearly not a true Lugeon value,

but a close estimation for fluidified

and stable grout, which allowed the

progressive evolution of the effective

Lugeon value, and hence the progres-

sive reduction in transmissivity of the

rock, to be observed in real-time as the

injection progresses, similar to con-

tinuous water test, but with grout.

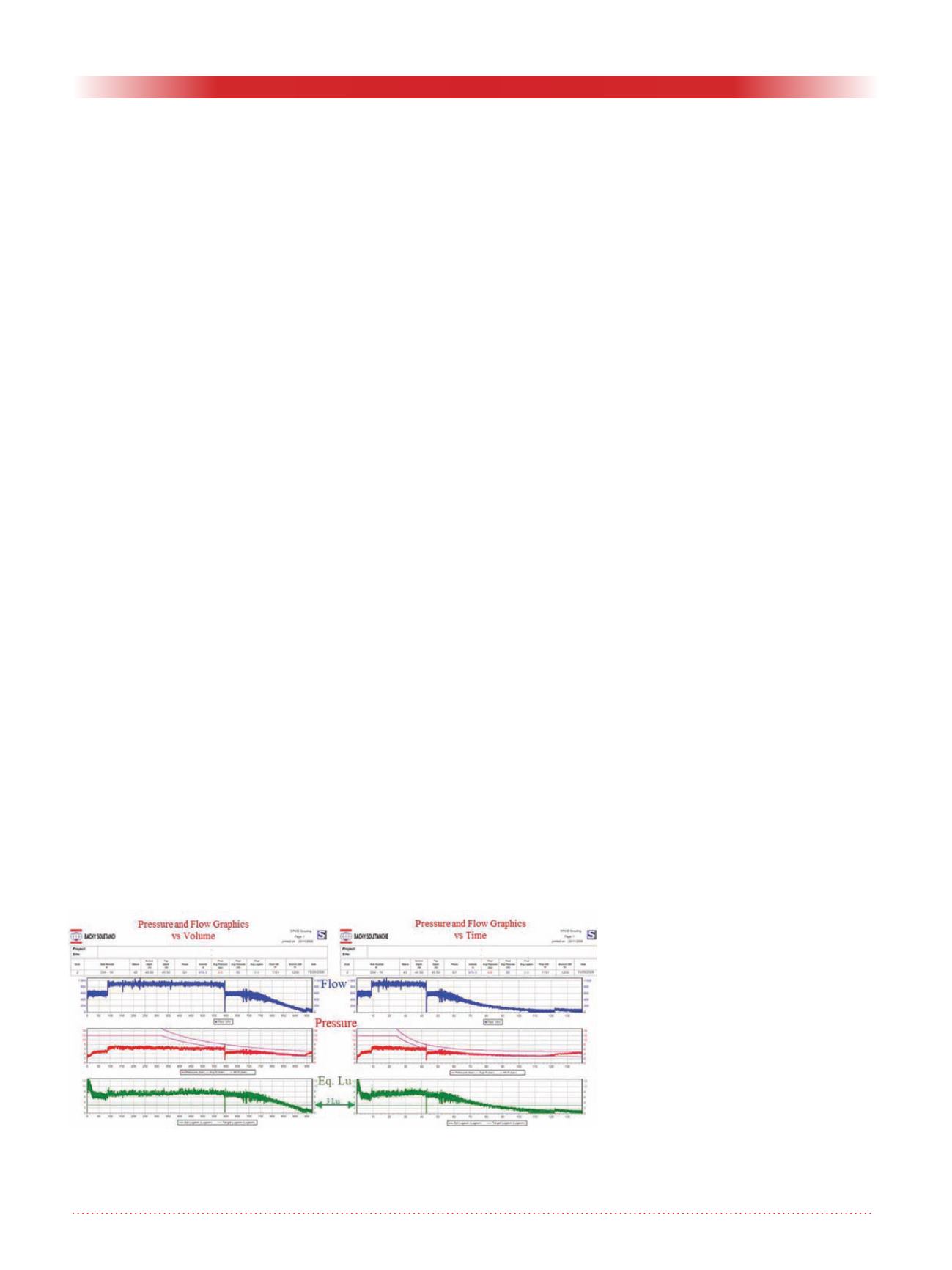

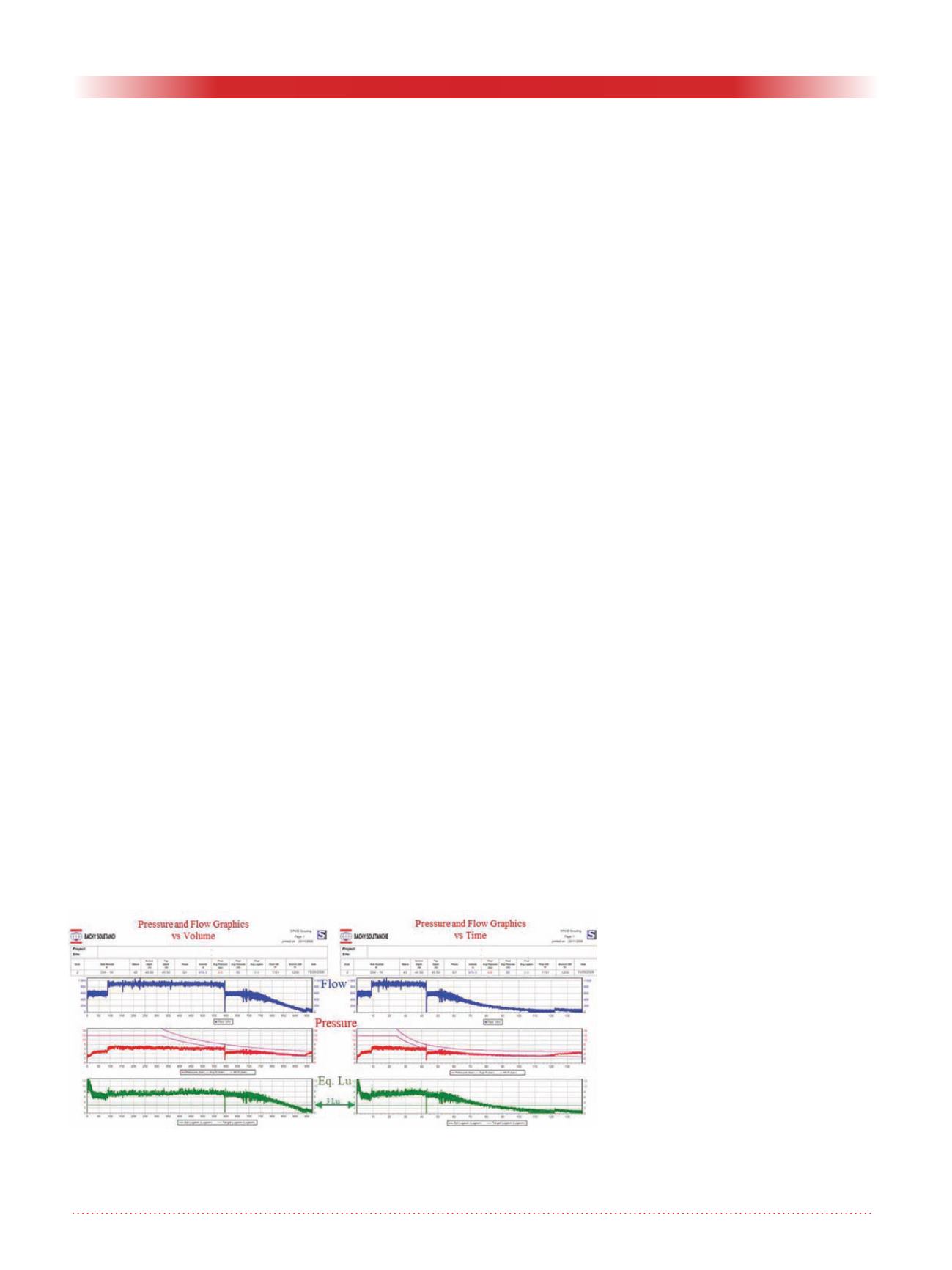

In the typical example illustrated in

Figure 2, it can be observed that at

the end of the injection the pressure

increases and flow rate reduces - clear

evidence that the rock is “tightening-

up’; but also that the injection has

continued until the Equivalent Lugeon

value has fallen below the speci-

fied maximum allowable value of 3

Lugeons. However, if the same graph-

ics are plotted against a timescale,

Figure 2 (right) it can be seen how

much effort was taken to achieve the

best possible’ refusal’, by continuing

the injection well beyond the point

where the specified 3 Lugeon criteria

had been met. It can be observed that

in this example the grouting continued

for half an hour after the specified

threshold, so that the refusal could be

demonstrated over the last 30 minutes

of injection.

Working in this conservative manner

achieved excellent results and ensured

for the client that there was no require-

ment for a further tertiary phase of

treatment, which would certainly have

added considerably to the cost and

duration of the works.

Grout curtain design

The methodology and scope of the

grouting works evolved throughout

the duration of the project in response

to ground conditions, and this evolu-

tion was documented and controlled

through the issue of detailed method

statements and technical memoranda.

The basic elements of the drilling and

grouting design processes included:

• Preparation of a 3D design model

of borehole geometry for works

phasing, management, control,

planning, and reporting using

CASTAUR programme

• Generation of instructions for

the drill crews using CASTAUR

programme

• Accurate setting out of drill hole

locations

• Drilling of boreholes to rock head

and installation of guide /liner

pipes and /or TaM pipes

• Survey of as built alignment of drill

holes using Boretrack /Maxibor

• Revision of the 3D design model

for as-built locations

• Design of injection parameters for

grouting, including GIN mode

• Generation of electronic grouting

and water testing instructions us-

ing SPHINX, including selection

of GIN value

• Sequencing of grouting pro-

grammes

• Drilling of preliminary injection

stages and water testing

• Review of injection parameters and

mixes using SPHINX and SCAN

3-D

• Drilling and injection in phases as

detailed in sections under SPICE

pump regulation

Figure 2. Injection rate (blue), Pressure (red), and Equiv. Lugeon (green)

values plotted against the injected volume (left). Injection rate, Pressure, and

Equiv. Lugeon values plotted against the injection duration (right).