Geotechnical News • March 2016

45

THE GROUT LINE

The remedial

cut off works

were executed

throughout with a

rigorous attention

to detail, utilising

continuous real

time control and

monitoring of the

accuracy of the

slurry wall excavation during progress

of each panel. The effectiveness of the

grouting works was verified during the

course of each injection by continuous

monitoring of the injection parameters,

in particular, the Equivalent Lugeon

value. The latest technology available

was employed for all elements of the

works, consistent with the need for

cost effectiveness.

Performance Criteria

Assessment Method

Results Achieved

5 Water absorption tests.

Av. water tightness < 3 Lugeons,

no individual result >10.

Multi-stage water absorption tests in inde-

pendent holes in between the rows of grout

holes.

Hole spacing in grout curtain to be not

greater than 10m but actual spacing to be

proposed by Sub Contractor. At least 3 depth

stages to be tested in each hole.

12 no. water test hole locations agreed with

the Engineer

Single step Lugeon tests executed in 2 no.

stages of all holes

5-step Lugeon tests executed over full length

of all holes

Average test hole spacing 11 m but tests

targeted in areas of increased grout take

Maximum value 1.6 Lugeons

Average value < 1 Lugeons

6 Ensure all of area to be treated is

covered.

Monitoring grout hole locations and plotting

diagrams to overlay results on treated area

and graphical plots of injections

All elements of the works con-

trolled by systematic surveying

and testing, and plotted in 3-D

CAD format for spatial verification

Table 2: Performance criteria, assessment, & results for curtain - extract from Black & Veitch

compliance report.

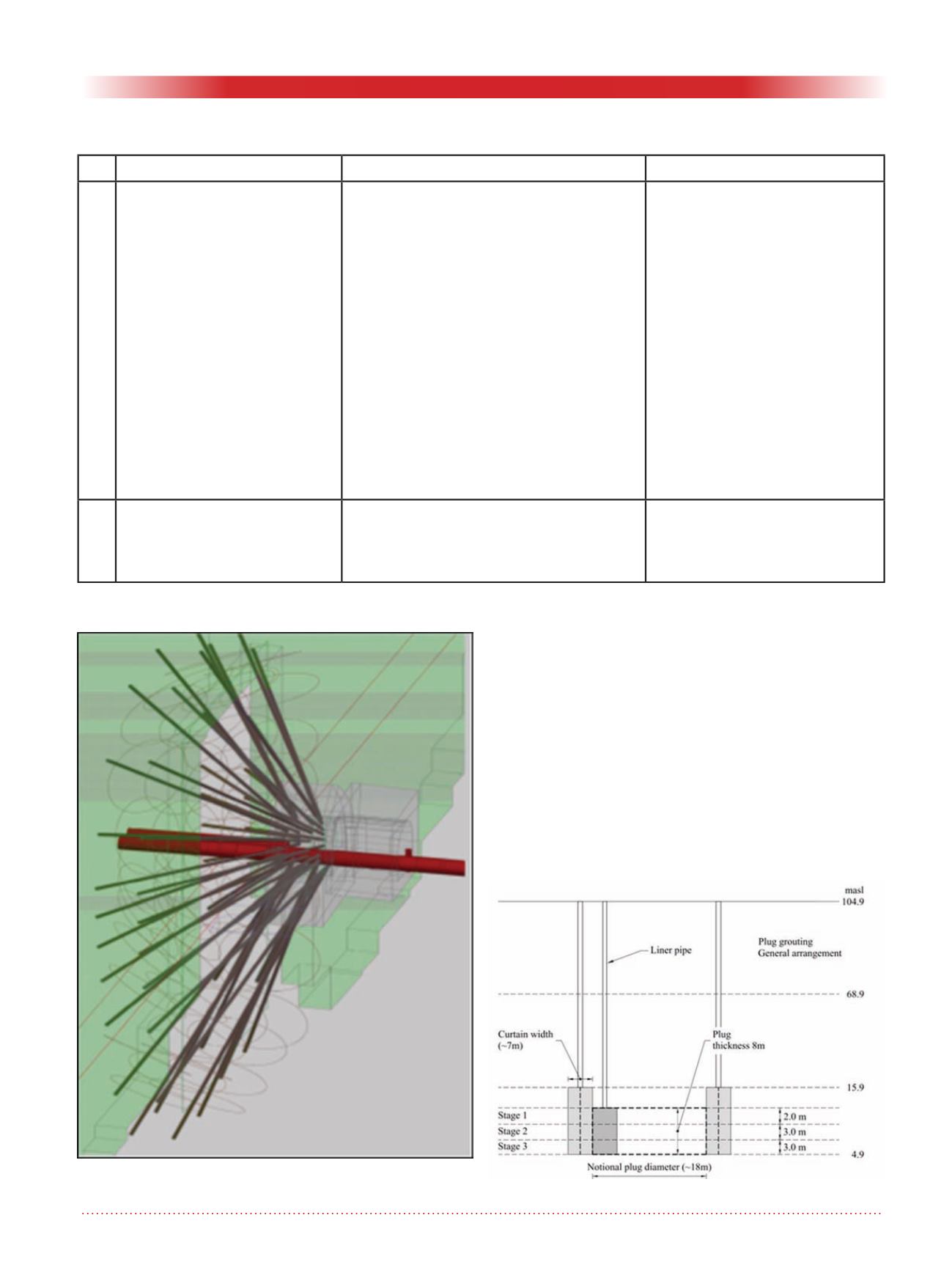

Figure 8. Plug grouting – general arrangement.

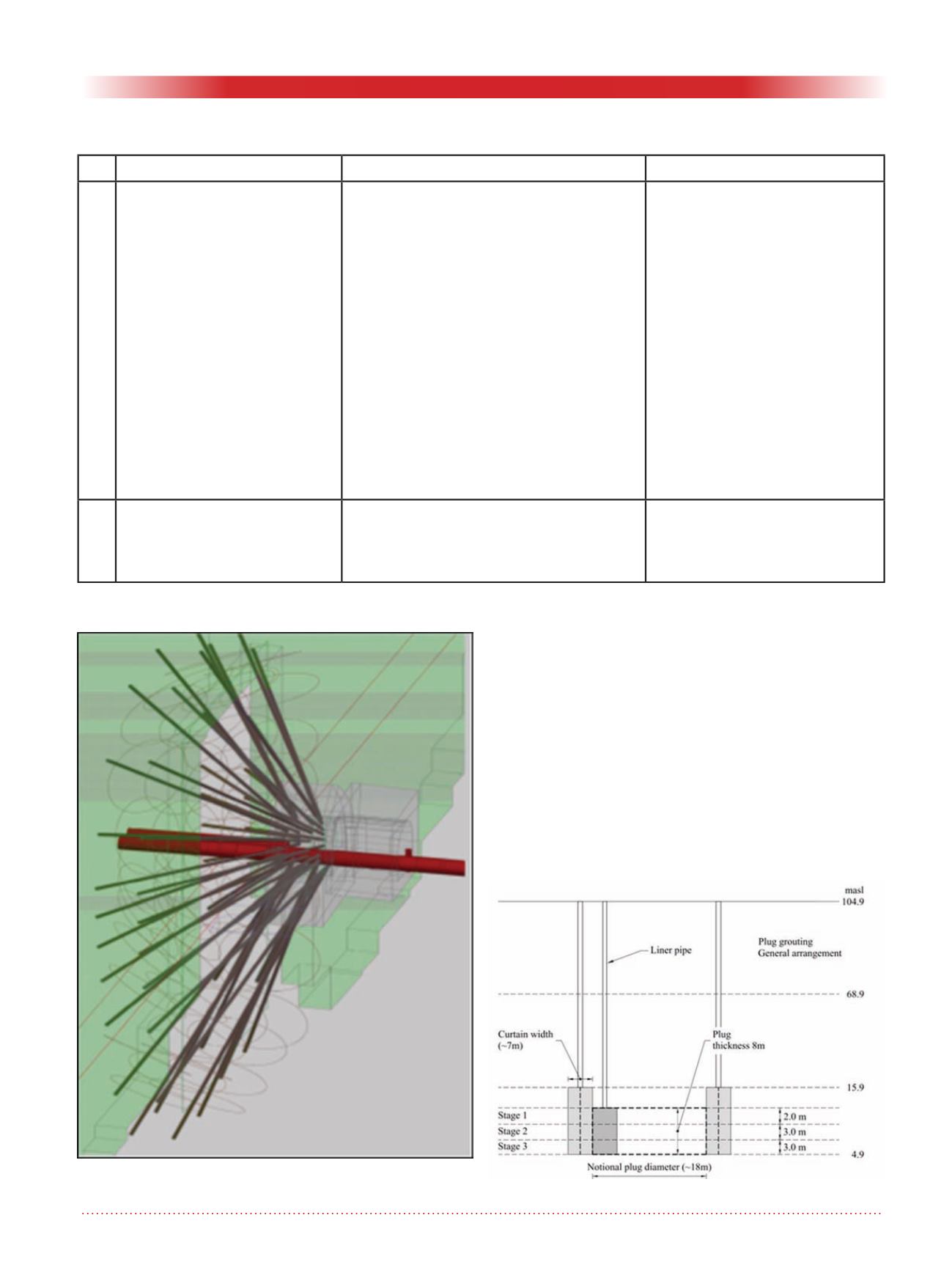

Figure 7. Link hole geometry around culvert, slurry wall,

and rock-head.