46

Geotechnical News • March 2016

THE GROUT LINE

Quality control of the works, including

supervision, management, and materi-

als testing, exceeded the requirements

of the specification in every respect,

and all performance

criteria were achieved. The dam

has been returned to service, fully

impounded to enhanced service level,

with no evidence of seepage. Piezo-

metric and weir analysis has verified

that the efficiency of the cut off has

been restored.

Case History 2 – LeeTunnel, England, 2013

Ground treatment was executed at

several locations for the tunnelling

works to facilitate the construction of

large and deep shafts and connecting

tunnels (90 m deep x 30 m diameter)

in fissured chalk where there was a

significant risk of sub-vertical fissures

and faults. On the basis of previous

experience of chalk grouting for the

Thames Barrier, Channel Tunnel, and

other projects, a figure of 5% of the

rock mass was used to characterise the

volume of groutable fissures gener-

ally, and 20% within any major faults

or crush zones. A single fault was

expected to be present within the main

overflow shaft excavation.

It was decided to use the GIN tech-

nique to reduce the risk of fissuring

the weak and weathered chalk. The

mix selected was C3S, a stable and

highly penetrating grout consisting of

OPC, de-flocculated bentonite slurry,

and fluidifier. This mix is well proven

over many years for both remedial

works and original grouting.

The depth of treatment for all of

the required areas was too great for

inclined drilling to address the risk of

vertical fissures, so the borehole grid

was reduced to a very conservative 1.5

m x 1.5 m spacing.

Stage 1 pre-treatment

Stage 1 comprised the pre-drilling,

along the centreline of the diaphragm

wall, using open-hole drilling tech-

niques with a cement-bentonite slurry

as flushing medium. The objective was

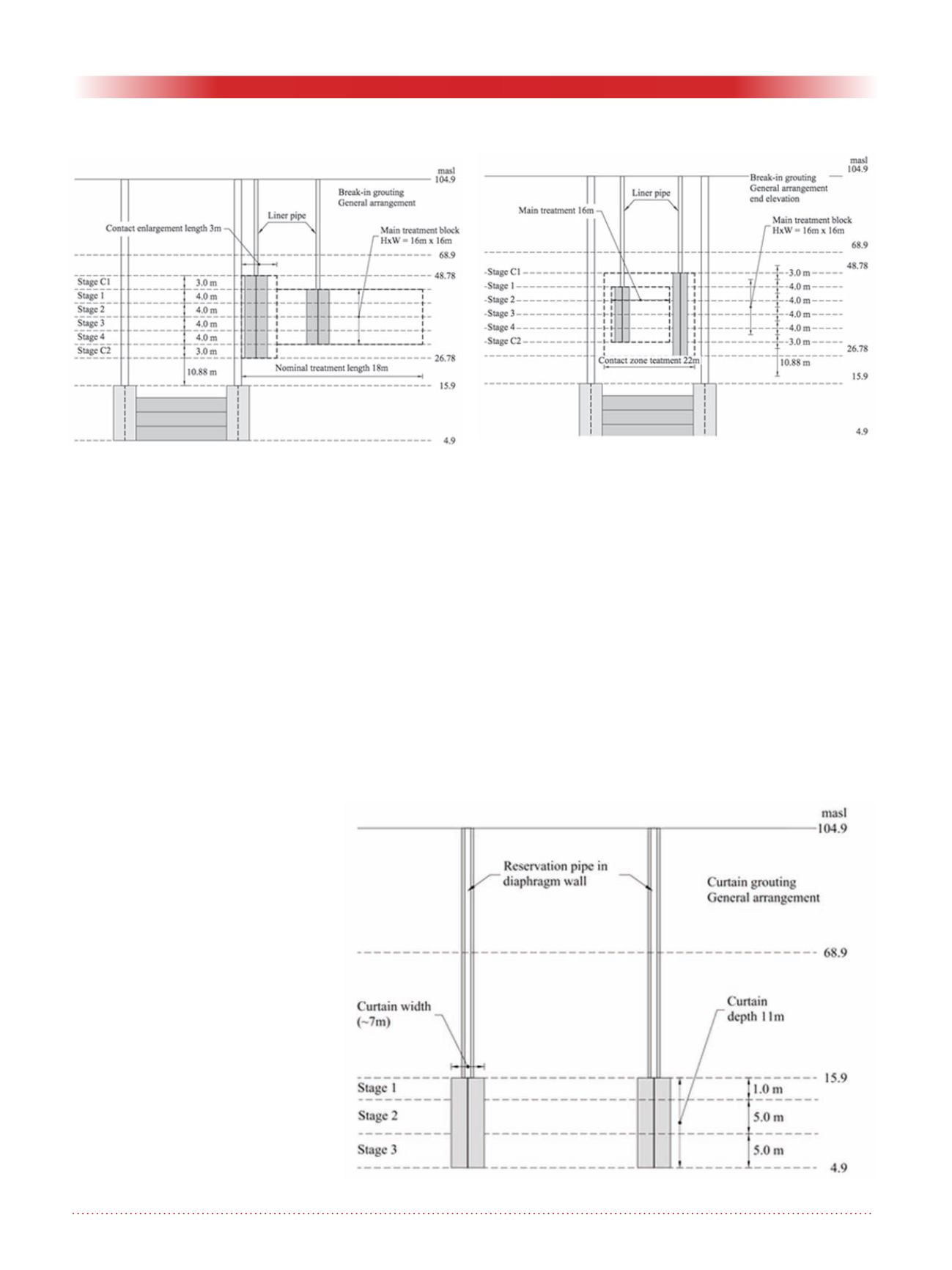

Figure 9. Break-in grouting - general arrangement.

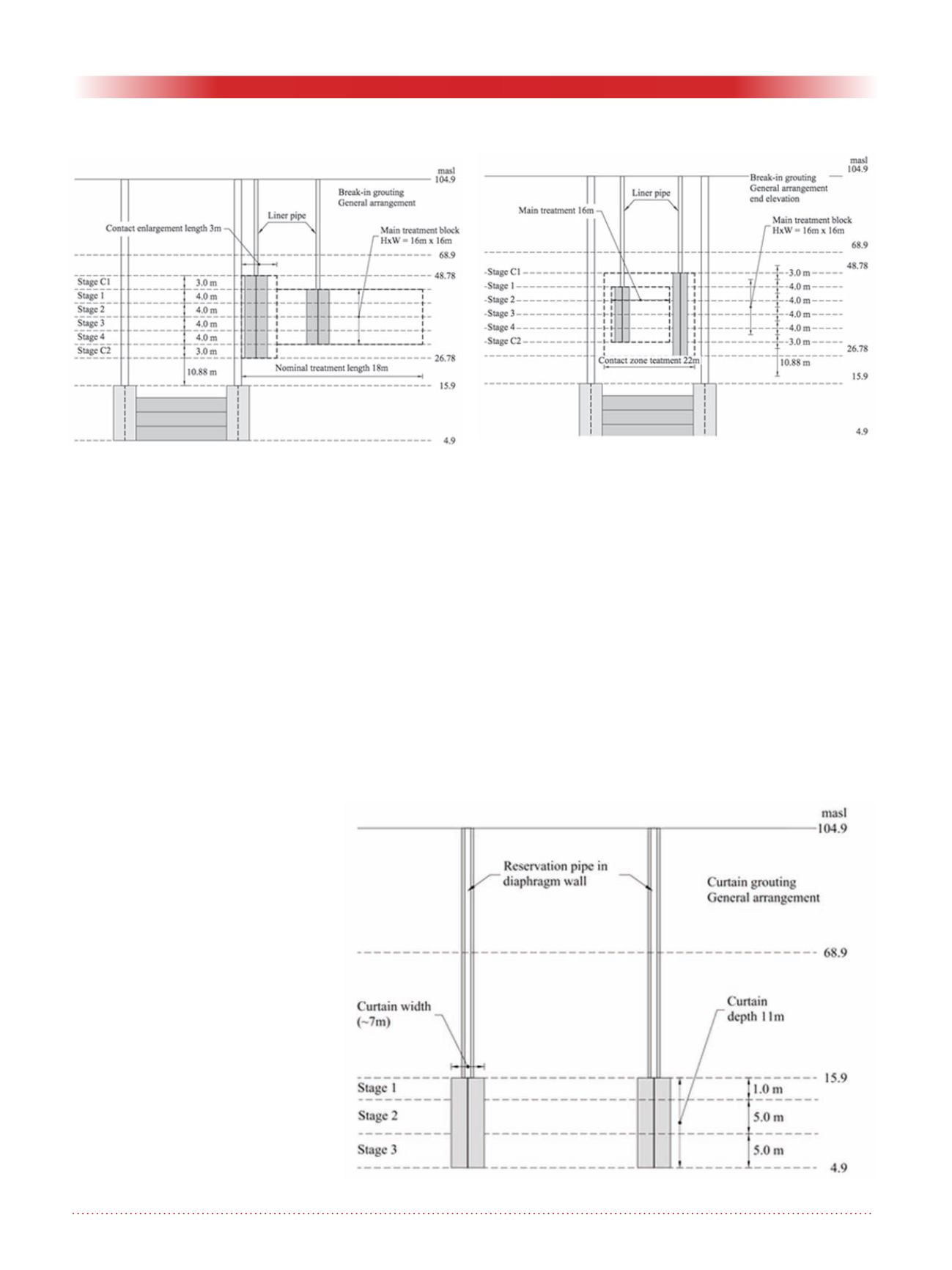

Figure 11. Grout in grouting - General arrangement.

Figure 10. Break-in grouting - General arrangement. End

elevation.