Geotechnical News • March 2016

43

THE GROUT LINE

• Analysis and reporting of grouting

results using SPHINX and SCAN

3-D

• Drilling of control holes, water

testing

• Preparation of 2D and 3D plots,

and tabulated analysis, using

SPHINX and SCAN 3-D

• Review of injection & water test

data

• Preparation of Black and Veatch

compliance documentation

Design and 3-D modelling

Due to the complex geometry of the

cut off, particularly around the culvert,

and the degree of uncertainty regard-

ing the profiles of the culvert planes

and rock head, it was considered

essential to establish a 3-D model to:

a. design the location of the grout

holes to ensure minimum spacing

b. define the zones of treatment for

the preparation of the electronic

grouting instructions

c. verify the continuity of the key cut-

off elements

A full 3-D model was prepared in the

CASTAUR-CAD geometry design

software, which was updated as the

works progressed on the information

from the driller’s logs, and the results

of borehole surveys using a Maxibor

instrument.

Grout curtain criteria

Maximum and average Lugeon values

were specified for the hydraulic con-

ductivity of the rock mass.

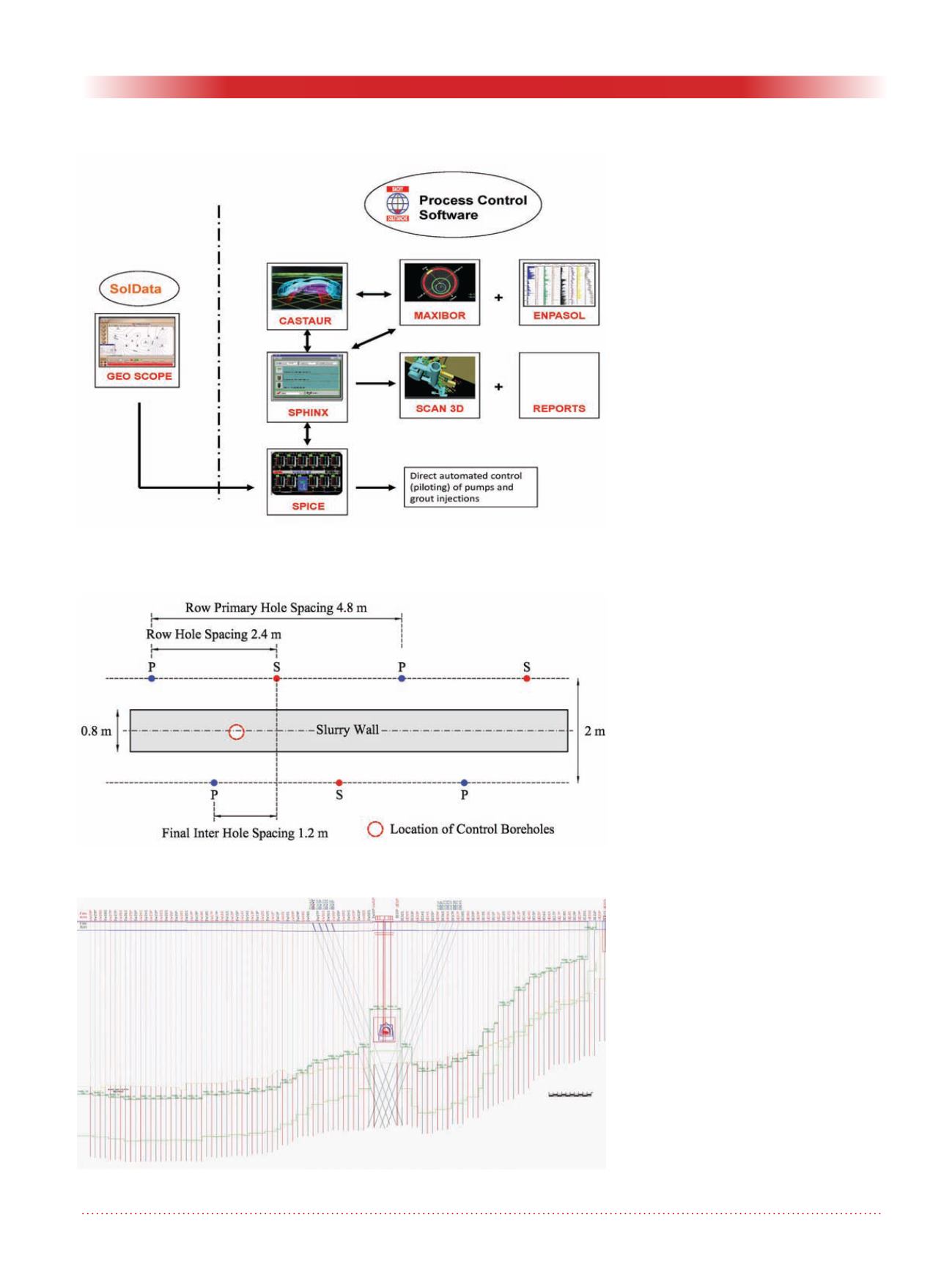

The specification called for a high

degree of control of the grouting

process, and the geometry of the grout

curtain, and required that the con-

tractor demonstrate continuity of the

cut-off. These issues were addressed

by employing an integrated system of

computer controlled grouting equip-

ment, and its dedicated IT suite of

software for the 3-D design, control,

management, and interpretation of

grouting operations. The system pro-

duces daily production reports in tabu-

lated and graphical analysis, and plots

Figure 3. Inter-relationship between key components of the control software.

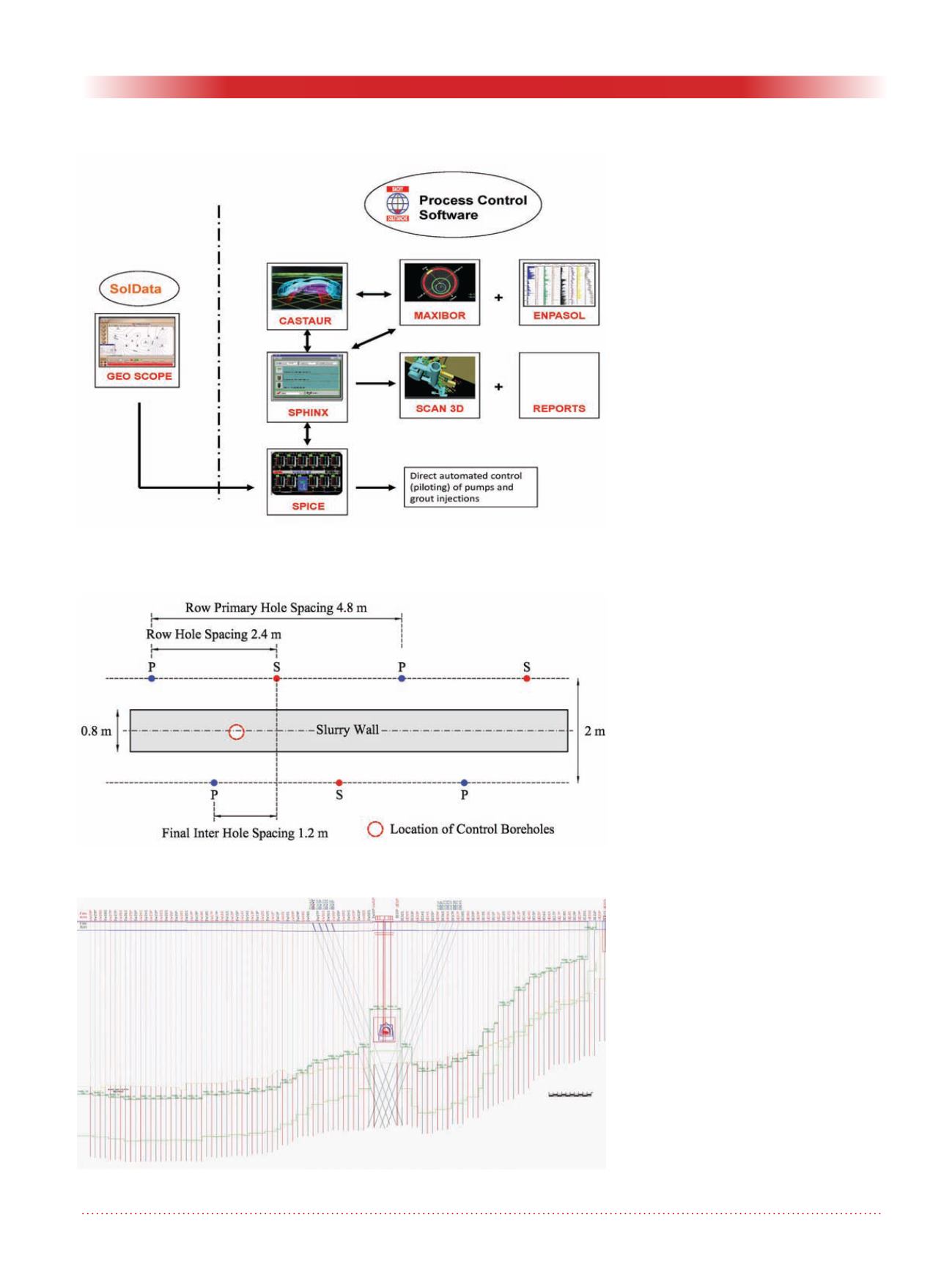

Figure 4. Grout hole / slurry wall geometry – plan.

Figure 5. Dam surface drilling geometry.